Brass pipe fittings deliver unmatched performance in high-temperature environments. You can rely on their exceptional heat resistance, durability, and corrosion resistance to handle demanding conditions. These fittings, like the Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow, provide a reliable solution for applications requiring strength and resilience. Their ability to maintain stability under extreme temperatures ensures consistent functionality. Whether you need them for residential, industrial, or commercial systems, brass fittings stand out as a dependable choice for efficient and long-lasting results.

Key Takeaways

- Brass pipe fittings are highly resistant to heat, maintaining structural integrity even in extreme temperatures, making them ideal for hot water and industrial heating systems.

- Their exceptional durability under mechanical stress and vibration ensures reliable performance, preventing leaks and maintaining system efficiency.

- Brass fittings offer superior corrosion resistance compared to steel and plastic, extending the lifespan of piping systems and reducing maintenance costs.

- The versatility of brass fittings allows them to be used in various applications, including residential plumbing, HVAC systems, and industrial setups.

- Choosing high-quality products like the Legines Brass Pipe Fitting ensures enhanced system efficiency and reliability, thanks to their robust construction and precise design.

- Brass fittings require less maintenance than steel, as they do not need protective coatings to prevent rust, making them a cost-effective choice for long-term use.

- Installation of brass pipe fittings is straightforward, making them accessible for both professionals and DIY enthusiasts, ensuring secure and leak-proof connections.

What Are Brass Pipe Fittings and Their Common Uses?

Definition of Brass Pipe Fittings

Brass pipe fittings are essential components in plumbing and piping systems. These fittings connect, redirect, or terminate the flow of liquids or gases within a system. Made from an alloy of copper and zinc, brass fittings offer a unique combination of strength, flexibility, and resistance to wear. Their ability to withstand high temperatures and pressures makes them a preferred choice for various applications. You will often find these fittings in systems where durability and reliability are critical.

The design of brass pipe fittings ensures secure connections between pipes. They come in various shapes, such as elbows, tees, and couplings, to accommodate different system requirements. The material’s natural corrosion resistance enhances its longevity, even in challenging environments. Whether you are working on a residential plumbing project or an industrial setup, brass fittings provide a dependable solution.

General Applications of Brass Pipe Fittings

Residential Plumbing Systems

In residential settings, brass pipe fittings play a vital role in ensuring efficient water distribution. You can use them in hot and cold water supply lines due to their excellent thermal stability. Their resistance to rust and corrosion ensures that your plumbing system remains functional for years. Brass fittings are also easy to install, making them a popular choice for homeowners and plumbers alike.

For example, you might use a 90-degree elbow fitting to change the direction of water flow in tight spaces. These fittings maintain a secure seal, preventing leaks and ensuring consistent water pressure. Their versatility allows them to adapt to various pipe sizes and configurations, making them suitable for kitchens, bathrooms, and outdoor plumbing systems.

Industrial and Commercial Applications

In industrial and commercial environments, brass pipe fittings excel in handling demanding conditions. You will find them in systems that transport gases, chemicals, or high-temperature fluids. Their ability to resist mechanical stress and vibration ensures reliable performance in heavy-duty applications.

Industries such as manufacturing, HVAC, and oil and gas rely on brass fittings for their durability and efficiency. For instance, in HVAC systems, brass fittings connect components like boilers and heat exchangers, ensuring smooth operation under extreme temperatures. Their compatibility with different pipe materials, such as copper and steel, adds to their versatility in complex systems.

Brass pipe fittings also meet stringent safety and quality standards, making them a trusted choice for critical applications. Their robust construction and adaptability make them indispensable in both small-scale and large-scale projects.

Why Brass Pipe Fitting Is Ideal for High-Temperature Environments

Heat Resistance and Thermal Stability

Brass pipe fittings excel in high-temperature environments due to their remarkable heat resistance. The brass material maintains its structural integrity even when exposed to extreme temperatures. You can rely on these fittings to perform consistently without warping or deforming. This stability ensures that your systems operate efficiently, reducing the risk of failures caused by thermal stress.

The thermal conductivity of brass also plays a crucial role. It allows heat to distribute evenly across the fitting, preventing localized overheating. This property makes brass pipe fittings an excellent choice for applications like hot water systems and industrial heating setups. When you need a reliable solution for high-temperature conditions, brass fittings provide unmatched performance.

Durability Under Mechanical Stress and Vibration

Brass pipe fittings offer exceptional durability, especially in environments with constant mechanical stress and vibration. The forged brass construction enhances their strength, allowing them to withstand heavy loads and sudden impacts. You can trust these fittings to remain secure and functional, even in demanding conditions.

In systems with moving parts or fluctuating pressures, brass fittings maintain their connections without loosening. This reliability ensures that your piping systems stay leak-free and efficient. Whether used in HVAC systems or industrial machinery, brass pipe fittings deliver long-lasting performance under challenging circumstances.

Corrosion Resistance in High-Temperature Systems

Corrosion resistance is another key advantage of brass pipe fittings. High-temperature environments often accelerate corrosion in materials like steel, but brass resists this degradation effectively. You can use brass fittings in systems exposed to moisture, chemicals, or high heat without worrying about rust or material breakdown.

This resistance extends the lifespan of your piping systems, reducing maintenance costs and downtime. Brass fittings also retain their appearance and functionality over time, making them a cost-effective choice for both residential and industrial applications. When you prioritize durability and reliability, brass pipe fittings stand out as a superior option.

Comparing Brass Pipe Fitting to Other Materials in High-Temperature Conditions

Brass vs. Steel

Heat Conductivity and Resistance to Rust

When comparing brass to steel, you notice significant differences in heat conductivity and rust resistance. Brass conducts heat more efficiently than steel. This property ensures even heat distribution across the fitting, reducing the risk of localized overheating. In high-temperature systems, this advantage enhances performance and reliability.

Steel, while strong, is prone to rust when exposed to moisture or humid environments. Brass, on the other hand, resists corrosion effectively. This resistance makes brass fittings a better choice for systems that encounter both high temperatures and moisture. You can rely on brass to maintain its integrity and appearance over time, even in challenging conditions.

Maintenance and Longevity

Brass pipe fittings require less maintenance compared to steel. Steel fittings often need protective coatings or treatments to prevent rust, adding to upkeep costs. Brass fittings, with their natural corrosion resistance, eliminate this need. This quality reduces maintenance efforts and ensures long-term reliability.

In terms of longevity, brass outperforms steel in many applications. Steel fittings may degrade faster in high-temperature environments due to rust and thermal stress. Brass fittings retain their strength and functionality, providing a cost-effective solution for extended use. Choosing brass ensures durability and minimizes the need for frequent replacements.

Brass vs. Plastic

Temperature Tolerance and Flexibility

Plastic fittings struggle to match the temperature tolerance of brass. Brass pipe fittings withstand extreme heat without losing their structural integrity. Plastic, however, can warp or melt under high temperatures, compromising system performance. For applications involving hot water or industrial heating, brass offers unmatched reliability.

Flexibility is another area where brass excels. While plastic fittings may seem flexible initially, they can become brittle over time, especially in high-temperature conditions. Brass maintains its flexibility and strength, ensuring consistent performance. You can trust brass fittings to adapt to various system demands without failure.

Strength and Durability Over Time

Brass fittings provide superior strength compared to plastic. High-pressure systems or environments with mechanical stress can cause plastic fittings to crack or fail. Brass fittings, with their robust construction, handle these challenges effortlessly. This strength ensures secure connections and prevents leaks.

Over time, plastic fittings degrade due to exposure to heat, UV light, or chemicals. Brass fittings resist these factors, maintaining their durability and functionality. For long-term applications, brass proves to be a more dependable choice. You gain peace of mind knowing your system will perform reliably with brass components.

Real-World Applications of Brass Pipe Fittings in High-Temperature Systems

Hot Water Plumbing Systems

You rely on hot water plumbing systems daily, whether at home or in commercial spaces. Brass pipe fittings play a critical role in these systems by ensuring efficient and reliable water flow. Their ability to withstand high temperatures makes them ideal for hot water supply lines. Unlike other materials, brass maintains its structural integrity under extreme heat, preventing leaks and ensuring consistent water pressure.

In addition to heat resistance, brass fittings provide excellent corrosion resistance. This quality ensures that your plumbing system remains durable, even when exposed to minerals or chemicals in water. For example, a 90-degree brass elbow fitting can redirect water flow in tight spaces without compromising performance. By using brass fittings, you enhance the longevity and efficiency of your hot water plumbing system.

Industrial Heating Systems

Industrial heating systems demand components that can endure intense heat and pressure. Brass pipe fittings excel in these environments due to their robust construction and thermal stability. You can find them in applications such as steam distribution, chemical processing, and heat exchangers. Their ability to resist mechanical stress ensures reliable performance, even in the most demanding conditions.

Brass fittings also offer compatibility with various pipe materials, including copper and steel. This versatility allows you to integrate them seamlessly into complex industrial setups. For instance, in a manufacturing plant, brass fittings connect pipes that transport high-temperature fluids, ensuring smooth and efficient operation. Their durability reduces maintenance needs, saving you time and resources in the long run.

HVAC Systems and Boilers

Heating, ventilation, and air conditioning (HVAC) systems rely on brass pipe fittings for optimal performance. These systems often operate under high temperatures and pressures, making brass an excellent choice. You can use brass fittings to connect components like boilers, radiators, and heat pumps. Their heat resistance ensures that your HVAC system functions efficiently without interruptions.

In boiler systems, brass fittings handle the circulation of hot water or steam with ease. Their corrosion resistance prevents material degradation, even in environments with fluctuating temperatures. This reliability ensures that your HVAC system remains operational and energy-efficient. By choosing brass fittings, you improve the overall performance and lifespan of your heating and cooling systems.

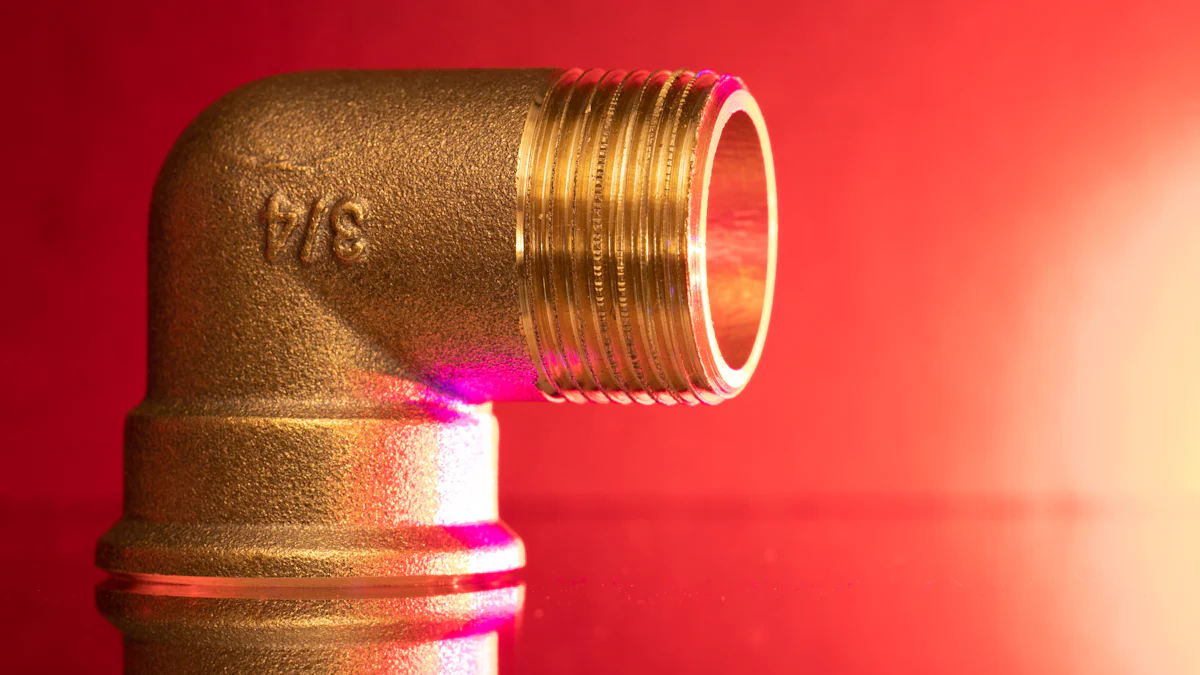

Product Spotlight: Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow

The Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow stands out as a premium solution for your high-temperature piping needs. This fitting combines precision engineering with high-quality materials to deliver exceptional performance in demanding environments. Whether you are working on residential plumbing, industrial systems, or commercial applications, this product ensures reliability and efficiency.

Key Features of the Legines Brass Pipe Fitting

-

Forged Brass Construction

The fitting is crafted from forged brass, which enhances its strength and durability. This material resists mechanical stress and vibration, ensuring long-lasting performance even in challenging conditions.

-

90-Degree Design

The precise 90-degree angle allows you to redirect flow efficiently. This design is ideal for systems requiring sharp turns without compromising the integrity of the connection.

-

Female NPT Threaded Connections

The fitting features female National Pipe Taper (NPT) threads, ensuring a secure and leak-proof seal when connected to male-threaded pipes. This design simplifies installation and enhances system reliability.

-

Wide Temperature Range

The Legines Brass Pipe Fitting operates effectively between -65°F and 250°F (-53°C to 121°C). This wide range makes it suitable for both hot and cold applications, providing versatility across various systems.

-

High Pressure Tolerance

With a maximum working pressure of up to 1200 psi, this fitting handles demanding tasks with ease. You can trust it to perform consistently under high-pressure conditions.

-

Corrosion Resistance

The brass material resists corrosion, ensuring the fitting remains functional and visually appealing over time. This feature reduces maintenance needs and extends the lifespan of your piping system.

Benefits of Choosing the Legines Brass Pipe Fitting

-

Enhanced System Efficiency

The fitting’s robust construction and precise design improve the overall efficiency of your piping system. It minimizes the risk of leaks and ensures consistent flow, even under extreme conditions.

-

Versatility Across Applications

You can use this fitting in a variety of settings, including hot water plumbing, HVAC systems, and industrial heating setups. Its compatibility with different pipe materials, such as copper and steel, adds to its adaptability.

-

Ease of Installation

The female NPT threads make installation straightforward. Whether you are a professional plumber or a DIY enthusiast, you will find this fitting easy to work with.

-

Compliance with Industry Standards

The Legines Brass Pipe Fitting meets the standards set by the Society of Automobile Engineers (SAE). This compliance ensures compatibility and reliability across various systems.

Why the Legines Brass Pipe Fitting Excels in High-Temperature Environments

The Legines Brass Pipe Fitting thrives in high-temperature systems due to its superior heat resistance and thermal stability. The forged brass material maintains its structural integrity under extreme heat, preventing deformation or failure. Additionally, its corrosion resistance ensures durability in environments exposed to moisture or chemicals.

This fitting also excels in handling mechanical stress and vibration. Its robust construction keeps connections secure, even in systems with fluctuating pressures or moving parts. By choosing the Legines Brass Pipe Fitting, you invest in a product that delivers consistent performance and peace of mind.

Available Sizes for Your Needs

The Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow comes in a range of sizes to suit your specific requirements:

- 1/8″ x 1/8″

- 1/4″ x 1/4″

- 3/8″ x 3/8″

- 1/2″ x 1/2″

- 3/4″ x 3/4″

These options allow you to select the perfect fit for your application, ensuring optimal performance and compatibility.

“The Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow is more than just a component; it is a reliable partner for your piping systems.”

By incorporating this fitting into your projects, you enhance the efficiency, durability, and reliability of your systems. Trust Legines to deliver quality and performance that exceed expectations.

Brass pipe fittings deliver unmatched performance in high-temperature environments. Their heat resistance, durability, and corrosion resistance make them a reliable choice for demanding applications. You can depend on products like the Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow to ensure efficiency and longevity in your systems. Compared to steel and plastic, brass offers superior reliability and reduced maintenance needs. Whether you are working on residential plumbing, commercial setups, or industrial systems, brass pipe fittings provide the ideal solution for consistent and long-lasting results.

FAQ

What makes brass pipe fittings suitable for high-temperature environments?

Brass pipe fittings excel in high-temperature environments due to their exceptional heat resistance and thermal stability. The brass material maintains its structural integrity under extreme heat, ensuring reliable performance. Its ability to distribute heat evenly prevents localized overheating, making it ideal for demanding applications like hot water systems and industrial heating setups.

Can brass pipe fittings resist corrosion in high-temperature systems?

Yes, brass pipe fittings offer excellent corrosion resistance, even in high-temperature systems. The material resists rust and degradation caused by moisture, chemicals, or heat exposure. This property ensures long-lasting performance and reduces the need for frequent maintenance, making brass a cost-effective choice for various applications.

How do brass pipe fittings compare to steel in high-temperature conditions?

Brass pipe fittings outperform steel in several ways. Brass conducts heat more efficiently, ensuring even heat distribution. It also resists rust without requiring additional coatings, unlike steel. These qualities make brass fittings more durable and easier to maintain in high-temperature environments.

Are brass pipe fittings better than plastic for hot water systems?

Yes, brass pipe fittings are superior to plastic for hot water systems. Brass withstands extreme heat without warping or melting, while plastic can lose its structural integrity under high temperatures. Brass also offers greater strength and durability, ensuring secure connections and long-term reliability.

What are the common applications of brass pipe fittings?

You can use brass pipe fittings in residential plumbing, industrial heating systems, HVAC setups, and commercial piping systems. Their versatility and durability make them suitable for transporting hot water, gases, and high-temperature fluids. They also connect components like boilers, radiators, and heat exchangers in complex systems.

How do I install brass pipe fittings?

Installing brass pipe fittings is straightforward. Use the female NPT threads to connect them securely to male-threaded pipes. Apply thread sealant or tape to ensure a leak-proof seal. Tighten the fitting with a wrench, but avoid over-tightening to prevent damage. Always follow the manufacturer’s guidelines for best results.

What sizes are available for brass pipe fittings?

Brass pipe fittings come in various sizes to suit different applications. For example, the Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow is available in sizes like 1/8″ x 1/8″, 1/4″ x 1/4″, 3/8″ x 3/8″, 1/2″ x 1/2″, and 3/4″ x 3/4″. These options allow you to choose the perfect fit for your specific needs.

Can brass pipe fittings handle high-pressure systems?

Yes, brass pipe fittings can handle high-pressure systems effectively. For instance, the Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow has a maximum working pressure of up to 1200 psi. This capability ensures reliable performance in demanding applications, such as industrial and commercial setups.

Are brass pipe fittings compatible with other materials?

Brass pipe fittings are compatible with various materials, including copper, steel, and plastic pipes. This versatility allows you to integrate them into different systems seamlessly. Ensure that the materials used together are suitable for the operating conditions to maintain system efficiency.

Why should I choose the Legines Brass Pipe Fitting for my project?

The Legines Brass Pipe Fitting, Forged 90 Degree Female Elbow offers unmatched quality and performance. Its forged brass construction ensures durability, while its heat resistance and corrosion resistance make it ideal for high-temperature environments. With features like female NPT threads, a wide temperature range, and high-pressure tolerance, this fitting provides a reliable solution for residential, industrial, and commercial applications.

Post time: Dec-29-2024